Our Products - Plunger Pumps

"> Simplex Pump :

Simplex Pump :

A Simplex Pump is a reciprocating pump. This pump has a single liquid cylinder which forces liquid out through the top outlet on both the in and the out stroke.

Duplex Pump :

The Duplex Pump is similar to the Simplex pump, having two pistons Instead of one, providing smoother operation with individual or common inlet & outlet.

Triplex Pump :

Triplex pumps are very similar to duplex pumps. They are reciprocating pumps with three cylinders. This pumps can be used for liner flow at high pressure.

Multiplex Plunger Pumps

Multiplex Plunger Pumps are very similar to Triplex pumps. They are reciprocating pumps with Multi cylinders. This pumps can be used for liner flow at high pressure.

Stream Jacketed Plunger Pumps :

Dencil Pumps manufacture stream jacketed metering pump for molten liquids.

The jacket Encloses the Check Valves and Gland Chamber. The valves are cartrige type and can be removed for servicing without dismantling thethe section and discharge connections.

High Pressure Plunger Pumps :

- High pressure pumps are essentially plunger pumps with three cilinders and three heads.

- They are essentially used for pumping high quantity / low quantity fluied at high pressures.

- Flow of liquid will be continues due to the operation of three plunger in a cyclic manner.

- The dry section are made with speciffically chosen material and manufacture to give the best performance fo a long period of time.

- Simillarly the fluid and operates are chosen as per the customers requirements or demand of the fluid.

Design Feature / benefits of Plunger pumps :

- For plunger pump discharge pressure to 200 Kg/cm2g (3000 psi), ideal for high pressure systems.

- Pneumatic and electric stroke length control available, automatic capacity control in response to standard 4-20MA process signal.

- Explosion proof motors available suitable for use in hazardous atmospheres.

- Lowflowrates accurate, reliable chemical feed.

- Accuracy ± 2%.

Design Facilities :

- Standard pump models selection considering Viscosity, Vapor pressure, Specific gravity.

- Piping layout (Acceleration losses & NPSHR)

- Computer aided design (CAD) for general Assembly.

Tests performed on each pump :

- Flow rate

- Power consumption

- Pressure test

Applications

- Basic intermediate and finished products, petrochemical and pharmaceuticals industries.

- Machine building, mining, metal processing, dilling and extraction technology

- Crude oil, natural gas, coal, nuclear power.

- Raw materials, liquid products, dairy products, pasta, baked goods, sweet tobacco

- Paper, cellulose, textiles, leather, synthetic, fibers or material, building materials, cleaners and detergent, film, tapes

- Water treatment, air cleaning, disposal techniques

- Dialysis, stored blood.

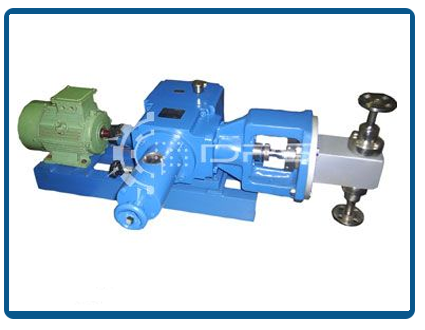

The Simplex Reciprocating Plunger Pumps is a packed plunger pump designed for heavy duty , continuous, accurate metering at higher flow rates and/or pressures. The positive displacement supplies a simple and virtually maintenance-free approach to accurate feed.

The Simplex Reciprocating Plunger Pumps is a packed plunger pump designed for heavy duty , continuous, accurate metering at higher flow rates and/or pressures. The positive displacement supplies a simple and virtually maintenance-free approach to accurate feed.

It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger. We can vary the capacity from zero to maximum by stroke length adjustment mechanism. The reciprocating motion of a plunger with ball check valves on each side of the pump body creates the pumping action.

This metering pump is also available in Simplex, Duplex and Multi Head models and holds an accuracy of ± 3% at steady state. The Stroke of the pumps is controlled by a precision machined, hardened slotted Crank, eccentric and connecting rod mechanism, which ensures a positive motion on both the forward and return stroke of the Plunger. The Pump discharge is variable while pump is running or at rest from Zero (0%) to full stroke (100 %)

| TECHNICAL SPECIFICATION | |

|---|---|

| Capacity | 0 TO 10000 LPH |

| Pressure | UPTO 0 TO 250 BAR |

| Material of Construction | As Per Your Requirements Which Include SS 304 / SS 316, ALLOY 20, HASTEALLOY, TITANIUM ETC. |

This is basically a Plunger Pump and is similar to Single acting Plunger Pump. The main difference is the liquid is sucked and discharged on both the suction and discharge stroke has two way inlet and outlet is provided for above operation. . It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger.

This is basically a Plunger Pump and is similar to Single acting Plunger Pump. The main difference is the liquid is sucked and discharged on both the suction and discharge stroke has two way inlet and outlet is provided for above operation. . It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger.

We can vary the capacity from zero to maximum by stroke length adjustment mechanism. The liquid part can be offered in SS 304, SS 316, Alloy 20, Hestalloy B or C, Teflon or any other material as required by the user.

Duplex Plunger Pumps are recommended for high pressure high head. They are offered in various models with flow rate up to 25,000 litres per hours and maximum pressure up to 450 kg/cm2. The higher grade corrosion and fatigue resistance material is used as ‘PLUNGER’ to suit application. Plunger Pumps are offered with metering device or as fixed stroke version. The advantage of these pumps to achieve higher capacities or different liquids can be pumped. All different heads can be set to desired flow rate and pressure or you have choice of selection of heads to run or shut off services not required without any trouble or interruption to each other heads.

Advantages:

- High Pressure

- Adjustable and Fixed Stroke Control for each different Head

- Two Different Liquid can be used

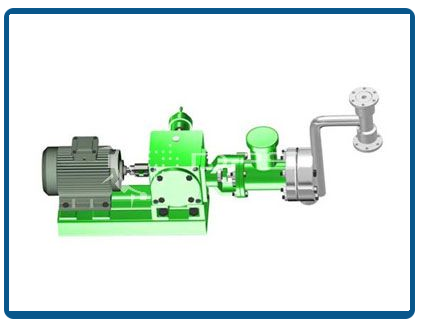

Dencil Pumps offers Multihead pump in Diaphragm & Plunger type to handle two or more liquid in one pump. It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger. We can vary the capacity from zero to maximum by stroke length adjustment mechanism. Multihead pump has more than two heads, which can be individually operated. The pumps are designed to ensure dosing of different chemicals in required ratio. The compact design of Multihead pump require less maintenance and the liquid end can be offer in SS 304, SS 316, Alloy 20, Hastelloy B or C, Titanium, PP, PVC, UHMW and Teflon etc. Multihead take major role in

Dencil Pumps offers Multihead pump in Diaphragm & Plunger type to handle two or more liquid in one pump. It is a positive displacement electric motor driven pump. Well equipped crank connecting rod mechanism convert the rotary motion of motor to reciprocating movement of Plunger. We can vary the capacity from zero to maximum by stroke length adjustment mechanism. Multihead pump has more than two heads, which can be individually operated. The pumps are designed to ensure dosing of different chemicals in required ratio. The compact design of Multihead pump require less maintenance and the liquid end can be offer in SS 304, SS 316, Alloy 20, Hastelloy B or C, Titanium, PP, PVC, UHMW and Teflon etc. Multihead take major role in

Heavy Chemicals,

Fine Chemicals,

Bulk Drugs,

Pharmaceutical,

Cement,

Sugar Industries,

Paper Industries,

Dyeing Unit,

Refineries,

Textiles Industries,

ETP,

Food and Plastic Industries etc.

'DENCIL' offers :

- Single Acting Multi Plunger & Diaphragm Pumps

- Double Acting Multi Plunger & Diaphragm Pumps

Dencil Pumps Manufacturers of steam jacketed metering pump for molten liquids. The jacketed encloses the Check Valves and Gland Chamber. The valves are cartridge type and can be removed for servicing without dismantling the suction and discharge connections.

Dencil Pumps Manufacturers of steam jacketed metering pump for molten liquids. The jacketed encloses the Check Valves and Gland Chamber. The valves are cartridge type and can be removed for servicing without dismantling the suction and discharge connections.

Steam Jacketed Plunger pumps are recommended for high temperature & low temperature & Molten Liquid.

They are used in

Chemical plant,

Fertilizer plant,

Water Treatment plant,

Soap plant,

paper Industries,

pharmaceutical Industries,

Thermal power projects,

plastic Industries.

The pump discharge is variable. While pump is running or at rest from zero (0%) to full stork (100%) by means of a precision machined crank equipped with a stork length adjustment mechanism. The stork of the pump controlled either manually (local) or Automatic Electrically (Remote). 4to 20 MA.

Wetted parts can be offered in S.S. 316 & 304, steel, P.V.C. & P.P. Teflon, P.V.D.F., Alloy 20 Hastalloy Borc, Titanium etc.

‘DENCIL’ offers

- Single Acting Steam Jacketed Plunger Pumps

- Double Acting Steam Jacketed Plunger Pumps

Remote Head Type Plunger Pumps is applicable in Case of handling liquids under extreme temperature conditions or in the case of explosive liquids; a remote head is provided which can be isolated by means of a Physical barrier from the surrounding environment. This arrangement can be provided on Plunger & Diaphragm Liquid Heads. Our Remote Head Type plunger pump comes with the option of customization Design according to the needs of the Clients.

Remote Head Type Plunger Pumps is applicable in Case of handling liquids under extreme temperature conditions or in the case of explosive liquids; a remote head is provided which can be isolated by means of a Physical barrier from the surrounding environment. This arrangement can be provided on Plunger & Diaphragm Liquid Heads. Our Remote Head Type plunger pump comes with the option of customization Design according to the needs of the Clients.

| TECHNICAL SPECIFICATION | |

|---|---|

| Capacity | 20000 lph |

| Pressure | Upto 1000 bar |

| Material of Construction | As per your requirements which include ss 304 / ss 316, alloy 20, hastealloy, titanium etc. |